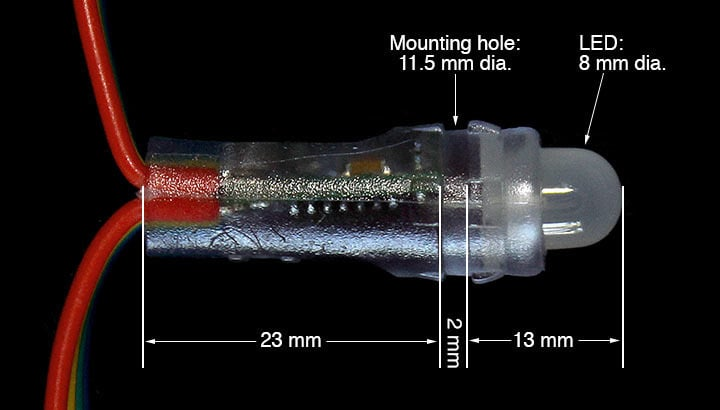

I’m in the process of replacing all my single-color christmas lights with addressable RGB LEDs, but the 12mm “bullet” form factor of them is different from the traditional incandescent mini lights, the 5mm wide angle LEDs, etc.:

You’d think they’d make C6/7/9 bulb covers that attach to them, but I have yet to find any for sale, anywhere. As such, I want to 3D print some, along with 12mm bullet pixel-sized replacements for my snowflake lights:

What’s some good filament I can get that will be reasonably clear and stay that way (without yellowing or getting too brittle) for several years’ worth of Christmas seasons, despite UV/rain/cold exposure?

(Bonus question: anybody know a good way to model the facets in those “strawberry” lights? The C7 bulbs on Thingiverse, such as this one, are all smooth, LOL.)

Edit: by the way, to be clear (pun intended): I don’t need optical clarity like the lens guy; scattering the light is fine. (In fact, doing that on purpose is kind of the point of modeling a faceted C7 bulb instead of a smooth one.) I just want to make sure that whatever part of the filament that doesn’t manage to be transparent is white, not tinted some dingy color.

I do happen to have some Inland “natural” PLA laying around and did a test print in that. It’s not too bad – only a little bit yellow at the wall thickness I’m using – but I fear for how it will hold up over time.

PETG is probably the way to go.

Honestly PLA would probably work just fine for this application as well. It’s not like the things are going to be enduring any mechanical load or high temperatures.

It’s really the UV I’m worried about. Even my commercially-made snowflake lights are pretty yellowed and brittle now, and I think they’re still less than a decade old (so less than 10 months of actual use).

That should tell you exactly why worrying about UV is a mug’s game. This is going to be an issue with all polymers, even tough old polycarbonate.

You could probably improve matters by clearcoating your objects after printing. The stuff used on car headlights after polishing is specifically for this purpose, and I believe Krylon makes an “arts and crafts” oriented clear coat that’s also billed specifically as UV protective and is probably cheaper.

That is a very good point!

deleted by creator

Well, the difference here is that if they yellow out in 3 years, you can simply print replacements for a few bucks instead of junking the string.